Factory Cheap Polythene Heat Sealing Machine - PUR Hot Melt Glue Laminating Machine For Fabric Nonwoven Leather Lamination – Yuanhua

Factory Cheap Polythene Heat Sealing Machine - PUR Hot Melt Glue Laminating Machine For Fabric Nonwoven Leather Lamination – Yuanhua Detail:

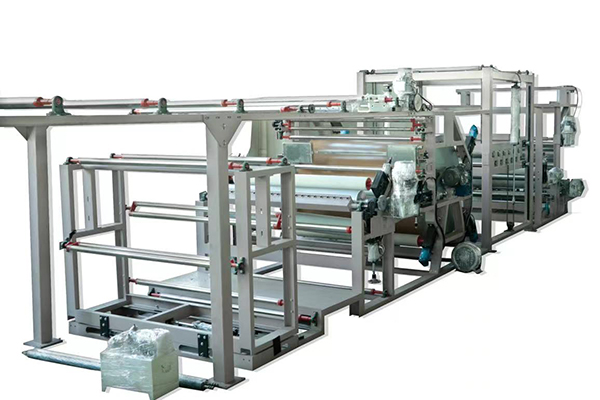

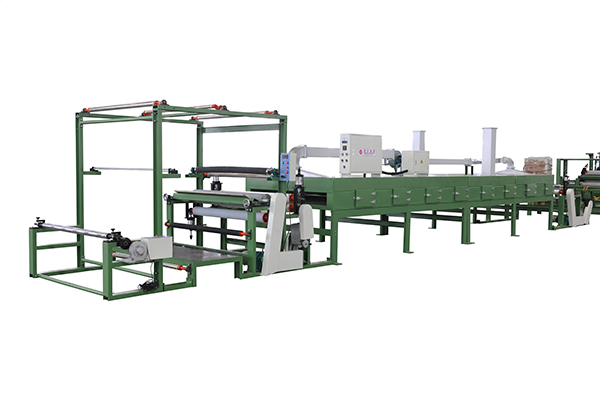

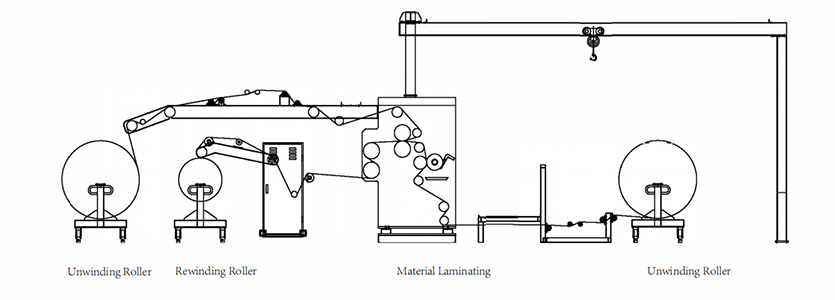

Our hot melt laminating machine is mainly consisted of fabric rewinding and unwinding units, fabric and film transmission systems and tension controller, film unwinding and lining or film carrier rewinding device, hot melt glue melting unit (optional), pump (optional), conduction oil source system (optional), glue dot transfer unit, laminating device, cooling device, PLC and other devices. It is compact, highly automatic and easy to maintain

| Model: | YH-028 |

| Maximum Material Width: | 1600mm |

| Machine Roller Width: | 1800mm (customizable) |

| Gluing Amount: | 5-80g/m2 |

| Machine Speed: | 10-60 m/min |

| Power: | 45.0 KW |

| Electric Current and Voltage: | Customizable |

| Estimated Net Weight: | 11000 KG |

| Estimated Dimension: | 11800 x 3400 x 3600 mm Customized |

Application

Applicable to the compound textile, non-woven products, TPU, PE, PTFE, EVA, PVC, Foam, non-woven fabric, artificial leather fabric laminating and film laminating…

Careers

Textile Industry, Home textile, Outdoor Industry, Medical Industry, Filter Material, Pet Products, Bedding Products…

Feature

The main component of PUR hot melt adhesive is the end isooxate polyhydrogen ester prepolymer. The bonding and toughness (elasticity) of PUR are adjustable, and it has excellent bonding strength, temperature resistance, chemical corrosion resistance and aging resistance.

1.PUR hot melt adhesive is a solid. When heated to a certain extent, it is melted into liquid and coated on the base material。

2.Moisture curing, no drying process, fast energy saving, the adhesive layer has certain flexibility, hardness and toughness.

3.Excellent Initial Strength, but also has crosslinking curing function, the final bonding strength is higher;

4.Single component, easy to industrial automation, mechanized operation, high production efficiency.

5.Because the product itself is solid, easy to pack, transport storage.

6.Does not contain any organic solvent, solid content of 100%, no pollution, non-toxic, green environment protection.

7.Excellent heat resistance, water resistance, chemical resistance, durability, etc.

8.As well as the production process is simple, high added value, viscosity and strength, speed and other advantages are favored.

9.Hot Melt Adhesive has stable performance high raw material utilization rate, fast production speed, high yield.

Filter Industry: Dust Bag, air filtration, etc…

Medical Industry: Protection Suit, Medical Mask etc…

Bags: Suitcase, Hand bag, etc…

Toys

Cloths: T shirt, Denim, Polyester, other clothes material etc…

Cloths: T shirt, Denim, Polyester, other clothes material etc…

Outdoor product: tent, bags, etc…

Water resistible and breathable Product: Sports Product, out door product

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Factory Cheap Polythene Heat Sealing Machine - PUR Hot Melt Glue Laminating Machine For Fabric Nonwoven Leather Lamination – Yuanhua , The product will supply to all over the world, such as: Surabaya, Mali, Rwanda, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!