Factory making Electric Cold Lamination Machine - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua

Factory making Electric Cold Lamination Machine - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua Detail:

Usage

Used for Sponge with nap textile, cloth, non woven products, decorative materials and etc laminating.

Application

Automotive industry ( car interiors, car seats)

Furniture industry ( office chairs, sofas, babies items, stuffings)

Footwear industry

Garment industry

Household cleaning products -PU-fibre scourers

Heat insulation – sound absorption, etc.

| Dimension |

5000mm*1800mm(Customized)*2200mm |

| Weight |

6000kg |

| Fire type |

Natural Gas |

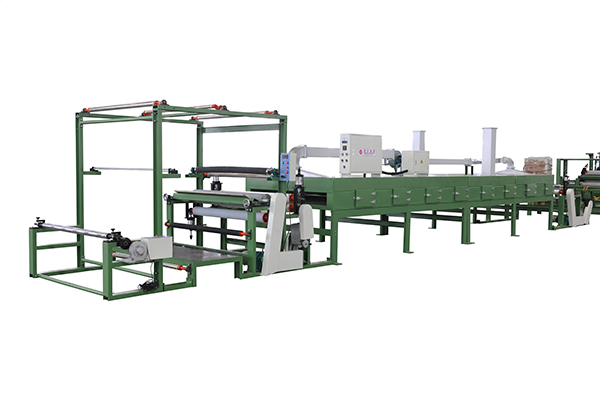

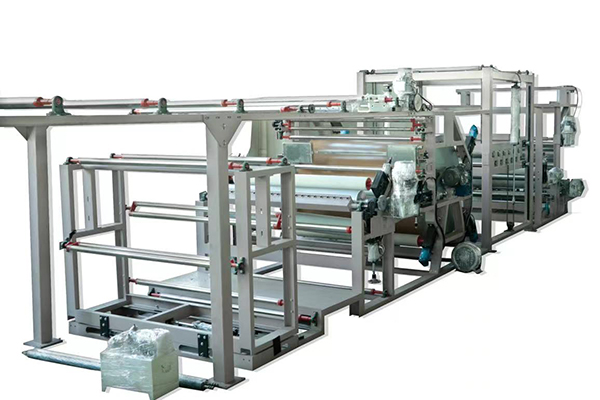

The Laminating Process Of Small Flame Laminating Machine

Before production of Flame Laminating Machine;The sponge release station, Fabric release station and the interlining release station (optional) must be loaded with material, the material rod shall be fixed and aligned with each other with the laminating device. The feed roller of the device is driven by a servo motor and its speed is controlled to maintain a steady supply of material required for continuous production in automatic mode.

Then the sponge will be transferred to the Laminating Device of the Flame Laminating Machine. The infrared control will control the material parallel.

Another Material Will be parallel feeding to the Flame Laminating Machine. This material will also go through the welding device and storage device to make sure laminating without stop. Before the material going into the laminating device of the flame laminating machine, the tension control device of Flame Laminating Machine will adjust the tension of roller to make sure it can fully bonding with Sponge.

The Two materials (Sponge,Material ) will be laminated by using flame. After laminating device, the finished product will go through trimming device of Flame Laminating Machine and then Rewinding.

Product detail pictures:

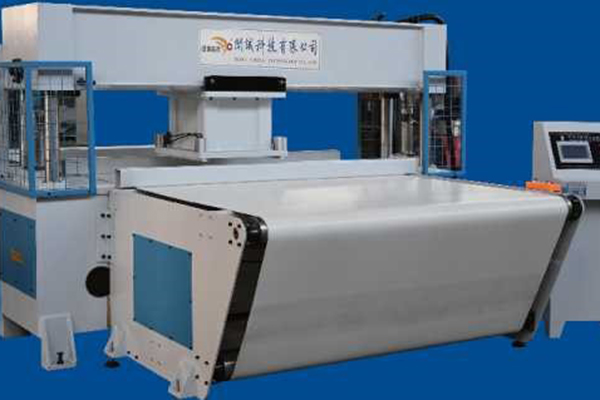

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for Factory making Electric Cold Lamination Machine - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua , The product will supply to all over the world, such as: Latvia, United States, Macedonia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.