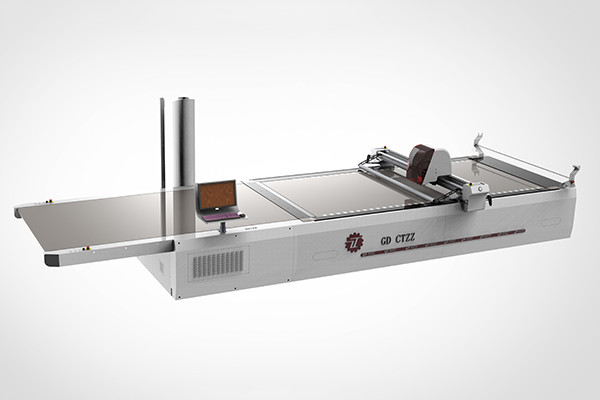

Factory supplied Plastic Wrap Sealing Machine - Fully Automatic Large Flame Laminating Machine For Sponge Bonding Car Interiors – Yuanhua

Factory supplied Plastic Wrap Sealing Machine - Fully Automatic Large Flame Laminating Machine For Sponge Bonding Car Interiors – Yuanhua Detail:

Feature

1.PLC, touch screen, servo motor control (optional), good synchronization effect, no tension automatic feeding control and tension automatic monitoring control, high continuous production efficiency.

2.With Constant tension suspension cooling system, make sure the product has better quality.

3.With unwinding, automatic edge alignment, storage rack and rewinding device, Suitable for mass production

4.The Flame Laminating Method: To melt the sides of Sponge, then to Laminating with other material that can achieve glue-less Laminating.

Application

Used For sponge and textiles, ,car interiors,bedding products, cloth, nonwoven products decorative materials and etc.

|

Dimension |

1500mm*2500mm(Customized)*3200mm |

|

Weight |

15000kg |

|

Power |

85kw |

The Laminating Process Of Large Flame Laminating Machine

Before production of Flame Laminating Machine;The sponge release station, Fabric release station and the interlining release station (optional) must be loaded with material, the material rod shall be fixed and aligned with each other with the laminating device. The feed roller of the device is driven by a servo motor and its speed is controlled to maintain a steady supply of material required for continuous production in automatic mode.

When the Sponged is released from the sponge storage device, it has been the end of sponge material when it came to the welding machine. ( The end of Sponge will be stored on the Storage device to weld the new sponge. The sponge should be stored on the storage device as much as possible, so that can have enough time to bond the new sponge. The function of the Sponge Storage device is too make sure the laminating machine can keep working without stop that can decrease unnecessary cost).

Then the sponge will be transferred to the Laminating Device of the Flame Laminating Machine. The infrared control will control the material parallel.

Another Material Will be parallel feeding to the Flame Laminating Machine. This material will also go through the welding device and storage device to make sure laminating without stop. Before the material going into the laminating device of the flame laminating machine, the tension control device of Flame Laminating Machine will adjust the tension of roller to make sure it can fully bonding with Sponge.

The third material will be feeding with the same way as the second material.

The three materials (Sponge,Material 1, Material 2) will be laminated by using flame. After laminating device, the finished product will go through trimming device of Flame Laminating Machine and then Rewinding.

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Factory supplied Plastic Wrap Sealing Machine - Fully Automatic Large Flame Laminating Machine For Sponge Bonding Car Interiors – Yuanhua , The product will supply to all over the world, such as: Mumbai, Saudi Arabia, Costa rica, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.