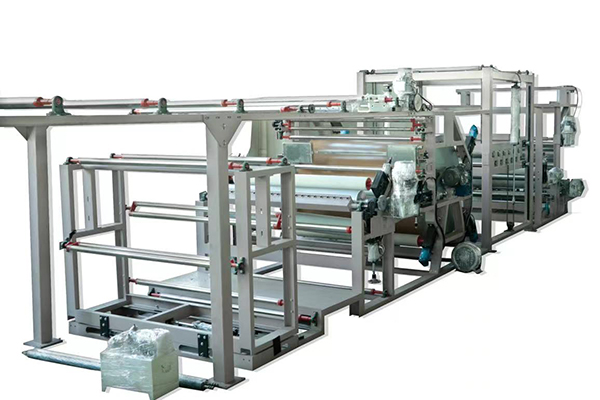

New Fashion Design for Wholesale Coating Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua

New Fashion Design for Wholesale Coating Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua Detail:

Application

| Model | YH-002 |

| Power | 380V/220V |

| Weight | 3000kg |

| Speed | 0-60m/min |

| Standard Roller Size | 1500mm*1800mm |

Feature

1.The Vertical Belt Water Glue Laminating Machine uses water-based glue or the white latex.

2.The Vertical Belt Water Glue Laminating Machine improves the quality of the products greatly, save cost.

3.The Vertical Belt Water Glue Laminating Machine has vertical structure, low breakdown rate and long service time.

4.Equipped with high quality heat resistance net belt to make sure the laminated materials contact closely with the drying cylinder, that can improve the drying effect, and make the laminated product soft, and strengthen adhesive fastness.

5.This leather laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

6.The Surface of heating roller is coated with Teflon paper in order to efficacious prevent the unevenly heating.

7.For clamp roller of the Vertical Belt Water Glue Laminating Machine, both hand wheel adjustment and the pneumatic control are available.

8.Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life

9. Customized manufacturing is available, we can customized the machine structure based on the feature of customers’ materials and customers’ need.

10.The Vertical Belt Water Glue Laminating Machine has very low maintenance cost and simple to maintain. And it is very easy to operate.

How to maintain the machine

1.The reducer should be replaced with lubricating oil every 6 months.

2.The Engine of this laminating machine should be replaced with lubricating every 12 months.

3.The chain needs to be properly lubricated and tensioned.

4.The gluing parts must be cleaned after use.

Application

Toys

Bags

Clothes

Carpets & Home Interiors

Different Home interiorproduct Laminating

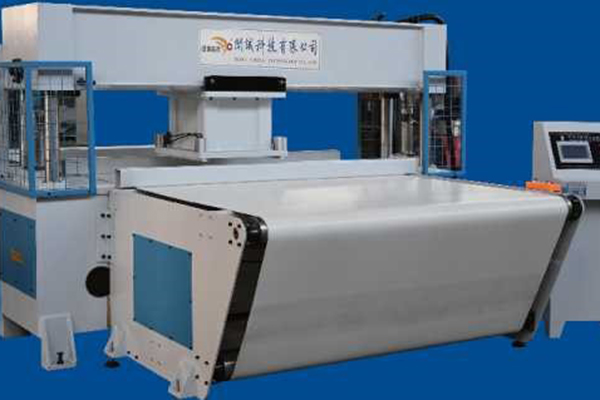

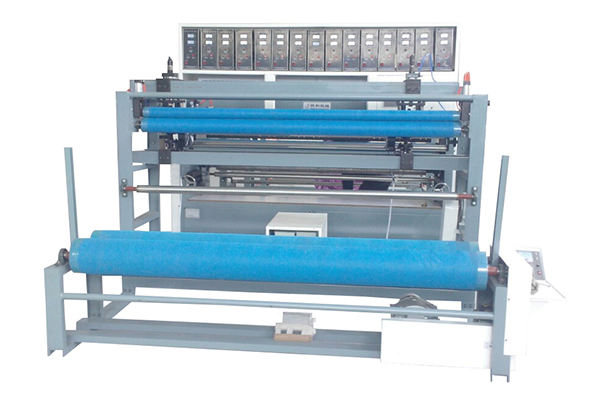

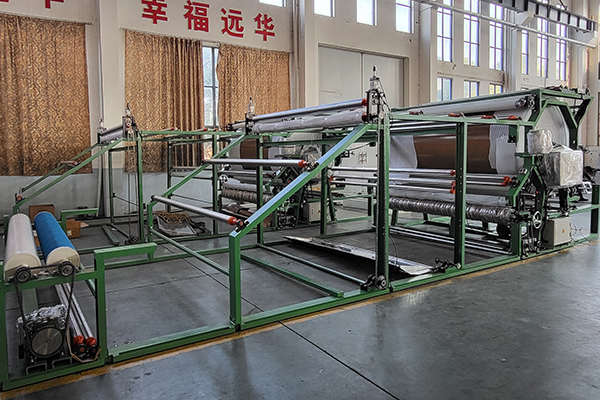

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for New Fashion Design for Wholesale Coating Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua , The product will supply to all over the world, such as: Nigeria, Buenos Aires, Colombia, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.