Newly Arrival Laminate Cold Press Machine - Automatic YH-016 Automatic Ultrasonic Quilting Embossing Machine For Fabric Embossing – Yuanhua

Newly Arrival Laminate Cold Press Machine - Automatic YH-016 Automatic Ultrasonic Quilting Embossing Machine For Fabric Embossing – Yuanhua Detail:

Work Theory

The longitudinal vibration of Ultrasonic Embossing Machine is generated by the installation of over-energy conversion, and the vibration amplitude is amplified by the horn. The amplitude and flowers wheel rotation driven by a motor when flowers round to press, the contact face, the amplitude between the roller and the amplitude of the fabric cutting to melt under ultrasonic mechanical effect and heat effect Slide away from the work surface, fabrics with pressure wheel drive to get to the function of cutting and printing from time to time ultrasonic embossing machine pneumatic local main work is completed in the process of processing pressure Pressure holding and other pressure working procedure control part to ensure the control of the whole machine workflow, and then achieve synchronous processing effect.

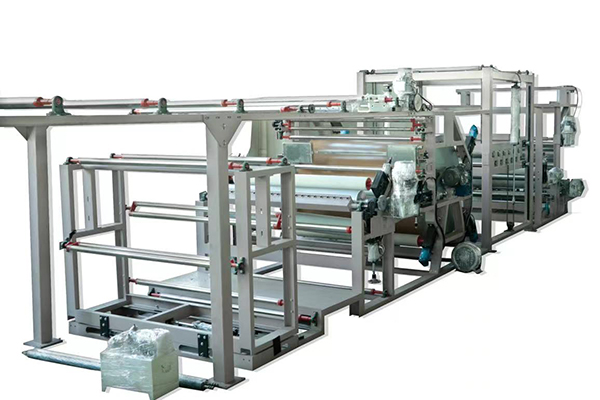

The Laminating Process Of Small Flame Laminating Machine

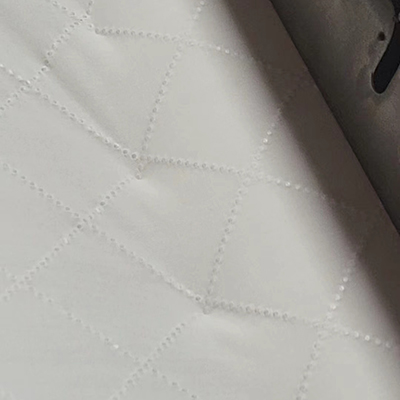

1. Without traditional seam broken connection state, strong adhesion, clear embossing that the ultrasonic embossing machine has the a better embossing effect, and more beautiful products;

2. After processing, the waste products have no pinhole and no seepage, and have more waterproof and heating effect;

3. The Ultrasonic Embossing Machine is easy to change the mold that can sew the kaleidoscope, complex discontinuity and symmetry patterns, according to customer needs to develop a variety of patterns;

4. The Ultrasonic Embossing machine has a high degree of automatic intelligence, the infrared automatic edging system can automatically correct each layer of materials, so that the upper and lower materials in the suture process always keep aligned, low processing loss, more smooth and stable products.

Application

The Ultrasonic Embossing Machine Widely used in Car cover, car cover chair cover, bag bag, shoes, cotton clothes, children’s wear, pillowcase, mattress, pillow, table, curtain, cold gloves, baby mat, wet urine mat, household goods, wardrobe, tent wardrobe, washing machine cover, electric milk, wardrobe, wardrobe, shoes hanging bag, PVC pool bottom, etc.

Customized Ultrasonic Embossing Roller mold(customized based on Customer’s Request):

Mattress or other Bedding Products:

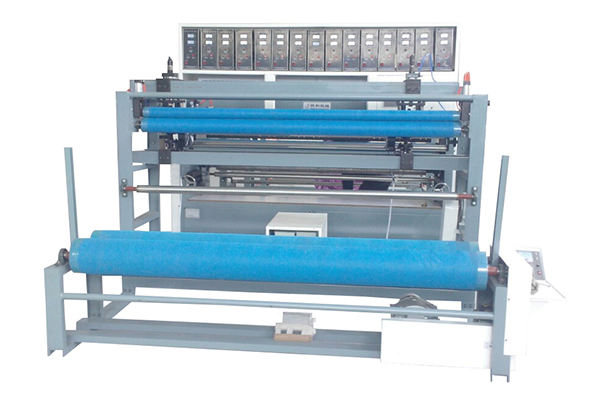

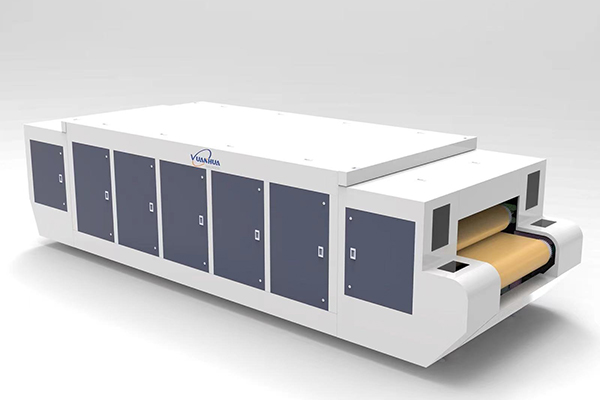

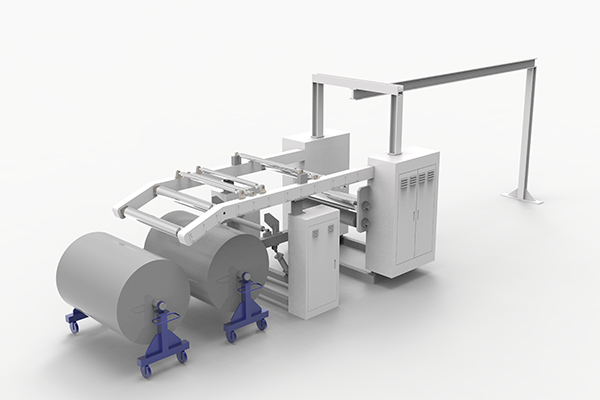

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for Newly Arrival Laminate Cold Press Machine - Automatic YH-016 Automatic Ultrasonic Quilting Embossing Machine For Fabric Embossing – Yuanhua , The product will supply to all over the world, such as: Slovenia, Azerbaijan, Greenland, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!