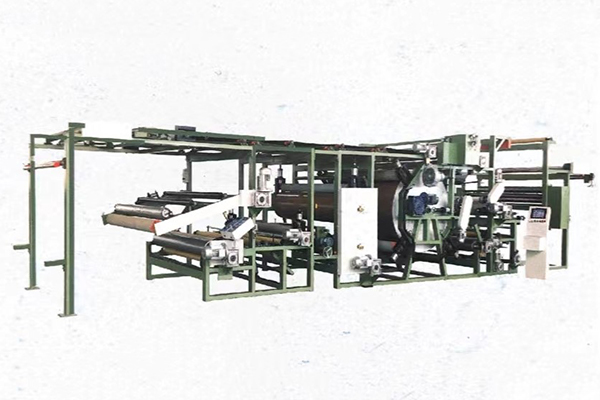

OEM/ODM Factory Laminator - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua

OEM/ODM Factory Laminator - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua Detail:

Usage

Used for Sponge with nap textile, cloth, non woven products, decorative materials and etc laminating.

Application

Automotive industry ( car interiors, car seats)

Furniture industry ( office chairs, sofas, babies items, stuffings)

Footwear industry

Garment industry

Household cleaning products -PU-fibre scourers

Heat insulation – sound absorption, etc.

| Dimension |

5000mm*1800mm(Customized)*2200mm |

| Weight |

6000kg |

| Fire type |

Natural Gas |

The Laminating Process Of Small Flame Laminating Machine

Before production of Flame Laminating Machine;The sponge release station, Fabric release station and the interlining release station (optional) must be loaded with material, the material rod shall be fixed and aligned with each other with the laminating device. The feed roller of the device is driven by a servo motor and its speed is controlled to maintain a steady supply of material required for continuous production in automatic mode.

Then the sponge will be transferred to the Laminating Device of the Flame Laminating Machine. The infrared control will control the material parallel.

Another Material Will be parallel feeding to the Flame Laminating Machine. This material will also go through the welding device and storage device to make sure laminating without stop. Before the material going into the laminating device of the flame laminating machine, the tension control device of Flame Laminating Machine will adjust the tension of roller to make sure it can fully bonding with Sponge.

The Two materials (Sponge,Material ) will be laminated by using flame. After laminating device, the finished product will go through trimming device of Flame Laminating Machine and then Rewinding.

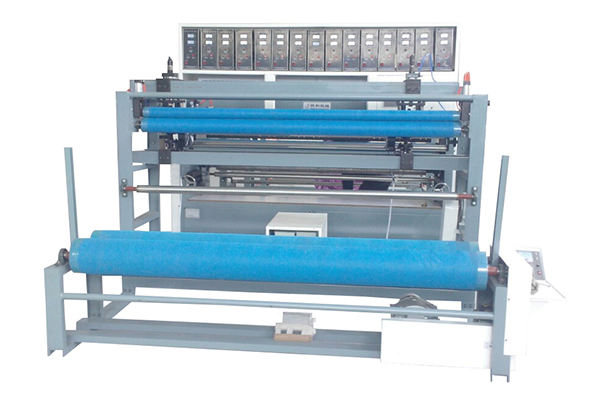

Product detail pictures:

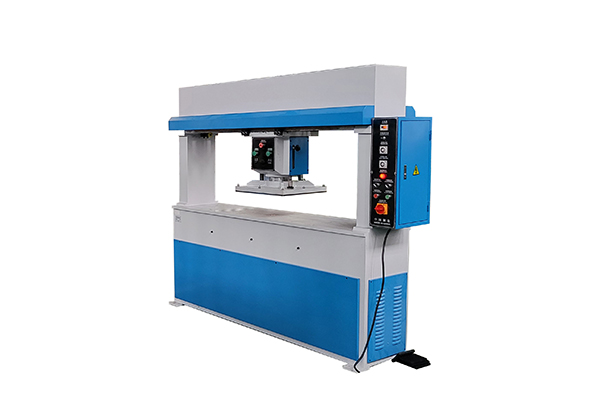

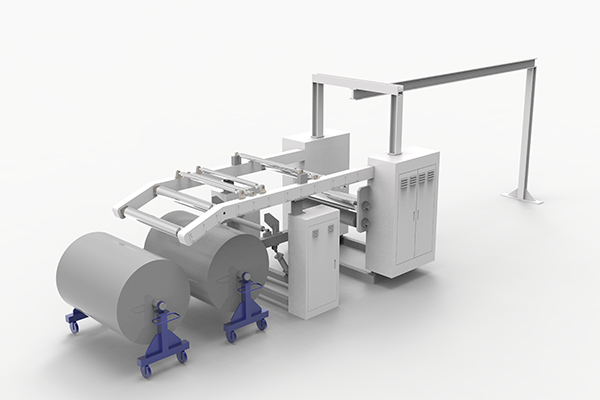

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for OEM/ODM Factory Laminator - High Efficiency Small Flame Laminating Machine For Sponge Foam Car Interiors Laminating – Yuanhua , The product will supply to all over the world, such as: Milan, Romania, Madras, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

We have been looking for a professional and responsible supplier, and now we find it.